Cattle Tick

Host: Abingdon Downs Station

Written by Anita Ganzer – Station Hand, Abingdon Downs Station.

Campbell, myself and our Head Stockman, Squeak, recently attended a course to become certified tick accreditors. The eventual outcome (should we receive our accreditation) is that we will legally be allowed to clear our own cattle of tick at Abingdon to be able to send them into tick free areas.

“The cattle tick, Rhipicephalus (Boophilus) microplus, is a serious economic pest of Queensland’s cattle industry. If left unchecked, this external parasite can significantly reduce cattle live-weight gain and milk production. It is also responsible for transmitting three blood-borne tick fever organisms, which cause sickness and death in cattle. Cattle ticks can also infest other species such as sheep, horses, goats, camels, alpacas, llamas, vicunas, guanacos and deer”. Ref: Dept Agriculture and Fisheries

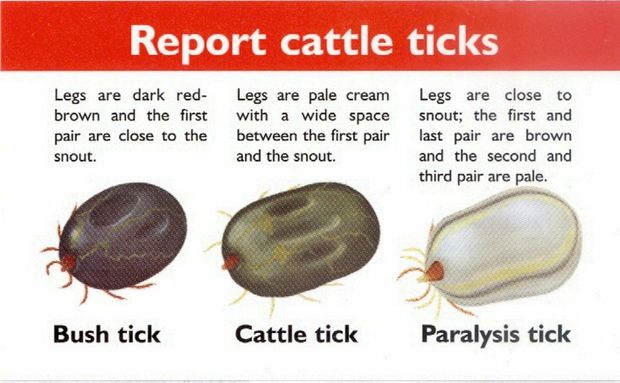

The Cattle Tick

The Cattle Tick

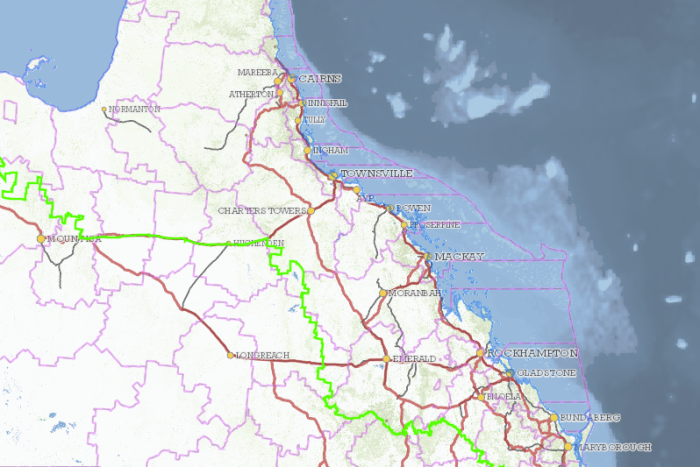

In Queensland there is an imaginary line that distinguishes two zones, one of which is declared “tick free” and the other as “tick infested”. Abingdon Downs is located in the “tick infested” zone. As I write that it sounds bad because we haven’t had any tick problems for a number of years now.

Tick Line in QLD. North of the line is “tick infested”, south of the line is “tick free”.

Tick Line in QLD. North of the line is “tick infested”, south of the line is “tick free”.

We have properties located in the “tick free” zone that we send our steers to for fattening. There is quite a process to follow for cattle leaving a “tick infested” zone to a “tick free” zone to finally arrive at their destination. Prior to leaving Abingdon the cattle require pre-treatment with a chemical application specifically for tick eradication. We mix the chemical into the dip ourselves and we are required to send dip samples away for analysis on a regular basis back to the manufacturer to ensure that chemical strength in the dip is as it should be. We use a plunge dip.

The Plunge Dip.

The Plunge Dip.

Pre-treatment begins four to seven days prior to cattle leaving Abingdon. The cattle are sent up the race in the dip yard then jump into the plunge dip. The dip itself is quite deep so that the cattle can fully submerge underwater to make sure every part of their body is covered in chemical. Once they walk out of the dip they are held in a holding pen with a concrete floor to allow for dripping and drying time. The excess chemical/water drains off the cattle and runs back into the dip to avoid wastage.

Swimming through the Dip.

Swimming through the Dip.

The holding yard for dripping and drying.

The holding yard for dripping and drying.

After the 4-7 day holding period the cattle are then transported to an accredited tick clearing facility near the “tick free” line (i.e. Richmond Sale Yards) where they are then “scratched” by an accredited person and then plunge dipped again. “Scratching” means feeling and scratching with your finger nails certain points on a beast where ticks can generally be located. If a tick is found on a beast then the entire herd will be retained in the yards at the clearing facility and re-checked after four to seven days as per treatment. It is incredibly important to make sure pre-treatment occurs prior to leaving Abingdon as the expense associated in retaining cattle in the sale yards for four to seven days is very costly. Cattle will need to stay in the sale yards until they are cleared, which could take up to a maximum of 35 days. If the cattle arrive at the clearing facility and have no tick (and after they are plunge dipped) they are free to go on their merry way to the tick free zone.

Scratching For Ticks.

Scratching For Ticks.

The purpose of us becoming certified tick accreditors is to eliminate the last process of sending the cattle to a clearing facility. We will be able to treat, “scratch” and clear our own cattle. The benefits for us will be enormous. Cost cutting will play a big part, but mostly it will benefit the cattle in a huge way. As we generally send weaner steers to our fattening blocks the whole dipping process is very hard on them. Going from Abingdon to Richmond (or Hughenden) can be a significant climate change for them. The Downs country can get really cold, where Abingdon is usually quite warm. Because they are weaners and not long been taken off their mothers they can be a little distressed. Adding a 650km (12 hour) journey in a truck to then be plunge dipped again in freezing cold water can certainly take its toll. Potentially it could take up to two weeks before they fully recover and start putting weight on in their new paddocks.

The rules and regulations associated with being a certified tick accreditor are quite intense. The Department of Primary Industries (DPI) does not treat this matter lightly and have stringent guidelines and practices in place. We will have to change our caps from cattle owners to DPI inspectors. All for the better of our cattle (and our bank account!).

The Dip Yards.

The Dip Yards.